Types Of Glass Construction

There are three types of glass construction:

Monolithic Glass – It is a single piece of glass constructed using one glass thickness. Monolithic glass is created using one of three methods: annealed, heat-treated, or tempered glass float.

Laminated Glass – It is made by combining two panes of glass fused with a middle layer of Polyvinyl Butylenes Film (PVB). PVB behaves like a bonding agent to hold broken glass in place, which creates a significant deterrent against forced entry and reduces the chances of flying pieces of broken glass. This type of glass is often used in car windshields and buildings/homes in hurricane-prone areas (e.g., Florida). If a glass panel breaks or shatters, it is improbable that both laminated panels will break simultaneously, which means that the remaining panel and interlayer will support the broken glass and keep it in place as edge protection until it is replaced or secured suitably.

An increasingly common interlayer is the SGP Interlayer (SPG stands for SentryGuard Plus Interlayer, created by American brand Dupont). It offers five times the tear strength and 100 times the rigidity of standard PVB. In the unlikely event of both panes of toughened glass failing, then the SGP will generally hold the glass in place. SGP offers enhanced impact performance and greater protection against severe weather. A variety of other interlayers are available, which apply a range of different technologies to the application. Structural interlayers can be used to enhance the strength of the glass, where high loadings are required. Colored interlayers can be used for privacy or purely decorative purposes. Other properties, such as sound-dampening and fire resistance, can also be incorporated into the interlayer.

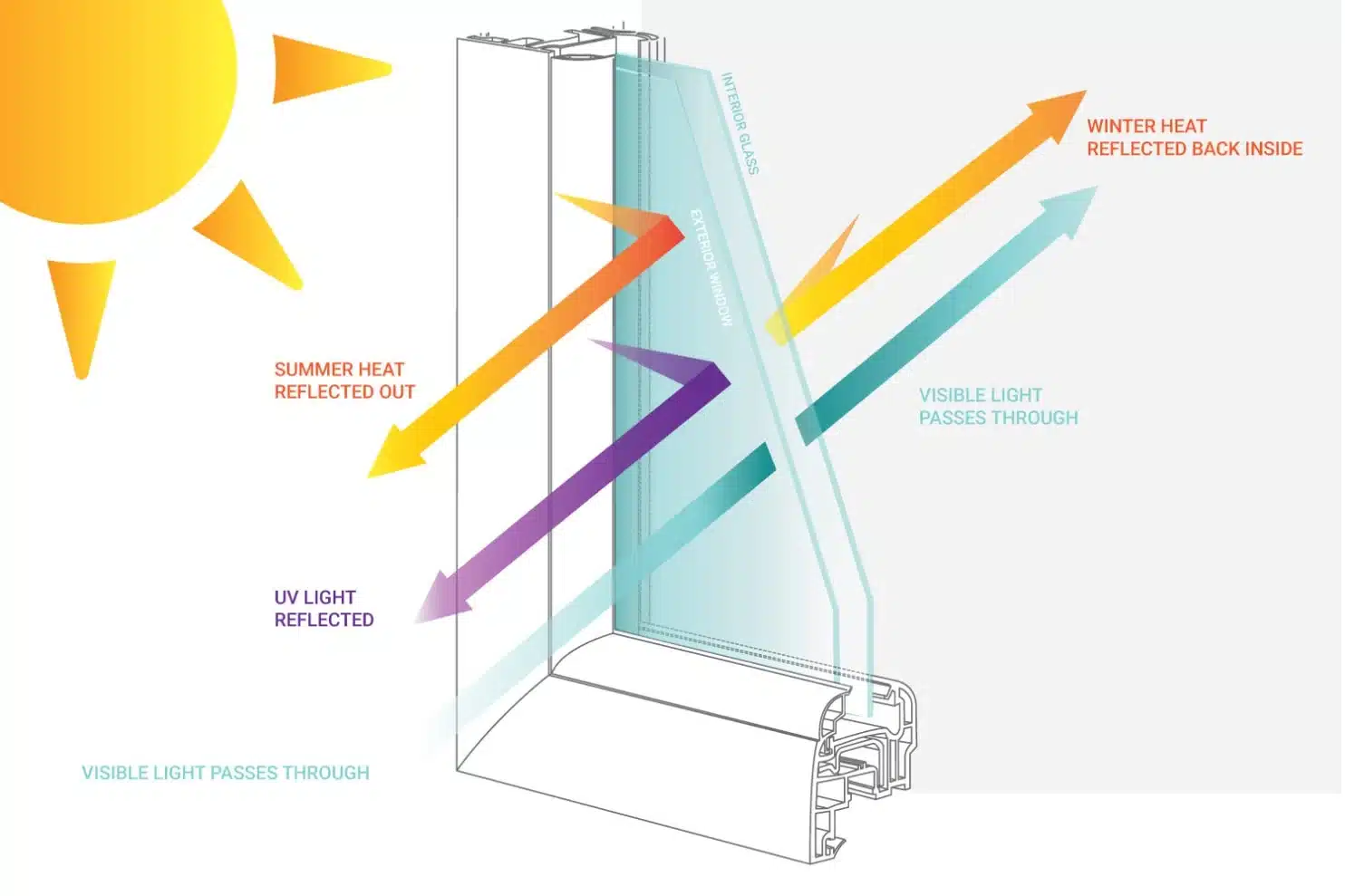

Insulated Glass – It is used to describe two pieces of glass separated by airspace. Airspace is created using spacers or edge seals found at the top and bottom of an Insulated Glass (IG) unit. Additionally, a sealant is applied to the edge seals to absorb excess water vapor that moves across the seal. The airspace between the glass layers dramatically reduces heat transfer through conduction and convection. Heavy and inert gases like Argon and Krypton are sometimes added to the airspace to slow down convection and minimize heat transfer. As a window film installation company, we know that insulated glass units are highly susceptible to thermal stress fractures. This happens when improper films with high heat absorption (e.g., dyed films) are applied. That is why we only use approved window films based on the customer’s glass type.

It’s essential to note that the aforementioned types of manufacturing processes usually create surface and edge flaws. This increases thermal stress, which is not the desired combination for window film applications.

Bullet-resistant glass is a thick glass made using multiple laminates of glass and polycarbonate. The numerous layers increase the chance of thermal stress fractures because they will heat and cool at varying temperatures. Therefore, solar control films are not recommended for bulletproof glass. A transparent film can be applied to the interior surface to hold glass shards together at impact to augment them.